Introduction

This is the first blog regarding a PIC18f14k50 USB IO board. This first session will focus on the design and building of the board, future sessions will take about software application that are being developed for this board.

At the start of the development of the board, I had the following “bullet spec” in mind:

- Development “starter” board for Jal(lib) USB developement

- It must have a USB 2.0 full speed connection

- Must be able to use it as a USB<->RS-232 interface converter, including 2 HW handshake signal, operate as a true RS-232 interface as well have the ability to use it for 5v signals (RS-232c, so it can be used to interface board towards other test boards that don’t have a MAX-232 level converter).

- Must be able to use it as a USB<->I2C interface board, either act a master or slave device

- Be able to add (small) daughter boards, in order use to the board as a HW/SW development platform (e.g. Remote control receiver, remote control transmitter etc)

- Homebrew friendly (easy to build, single sided PCB, no SMD component)

- Cheap (~10 Euro)

PIC selection

The first choice is what PIC to use, since I want to use it for JAL development (which restricts me to the PIC18F series), onboard USB Serial Interface Engine (SIE), should be a thru hole device and should run with 5v IO, I got the following list from the Micrcochip website:

Product Fam Price Fl EE RAM I/O

PIC18F13K50 $1.39 8 256 512 15

PIC18F14K50 $1.53 16 256 768 15

PIC18F2450 $2.23 16 0 768 23

PIC18F2455 $3.30 24 256 2048 24

PIC18F2458 $3.58 24 256 2048 24

PIC18F2550 $3.44 32 256 2048 24

PIC18F2553 $4.12 32 256 2048 24

PIC18F4450 $2.39 16 0 768 34

PIC18F4455 $3.51 24 256 2048 35

PIC18F4458 $3.79 24 256 2048 35

PIC18F4550 $3.65 32 256 2048 35

PIC18F4553 $4.33 32 256 2048 35

In the past I’ve used the 18f4550, which is a nice chip, but it is a bit expensive. I also have used the 18f2450 in a couple of projects; however, the main drawback is the lack of onboard eeprom (always handy for device specific settings). The recently introduced PIC 18f14k50 appears to be a nice compromise (almost similar to the 18f2450, but it is a bit cheaper and has onboard eeprom). Even though it is a low pin count device, I think it has enough IO pins. I have considered the 13k50, which is even a dime cheaper, but the flash and memory size is quite limited and the availability is a problem. However, the board can be used for both chips.

Schematic & PCB:

Once the PIC was selected, the design is straightforward:

I won’t go into the details of the “standard” PIC logic, consisting of the crystal (X1) + caps (C3/C4), ISCP connector (J1) and decoupling capacitor (C1).

There are two switches connected to the PIC, SW1 is can be used as a reset switch, SW2 is a generic switch with pull resistor. The DB-9 connector is connected via a MAX-232 level converter with the PIC (towards the internal UART PINs). The non-level shifted converted TX/RS signals are also connected to J3, in addition to the UART signals pin-5 is connected with the PWM/CCP unit of the PIC.

The 5 volt supply of the USB connector is used to power the board; the differential USB signal lines d+/d- are directly coupled from the PIC to the USB connector. Capacitor C5 is required for the internal 3.3v regulator.

The I2C header signals are also directly coupled with the MSSP unit, it can be used as a master or slave depending on the firmware, besides the 3 standard wires, also a 5v is available on the connector. The pull-ups can be enabled by placing the jumper (JP1).

Potmeter P1 is connector to AN5 of the PIC, this can be used for ADC experiments.

OK enough about the schematic. Richard Zengerink was so kind to draw the schematic and do the board layout. The board layout is depicted below, a PDF file of the layour is available in the SVN repository ( 18F14K50+EXTRA_lay_out.pdf

), this has the mirrored, 1:1 scale, so when printed on glossy paper with a laser printer, it can can be ironed into a copper cladded board, then etch it and drill it.

Building the board should not be too difficult; it took me about an hour to do the component assembly and solder it and perform some quick tests (check power connections, and check shortcuts)

A picture of the assembled board is depicted below:

Testing the board;

The first test is to connect a PIC programmer to the ICSP connector. Program the 18f14k50_led_switch_test.hex file on in the PIC and reset the board by doing a power off/on cycle (external reset is disabled in order to test SW1). The source code and Hex file are available in the jallib SVN repository

The application will turn on both LEDs for about 5 seconds, afterwards it starts to blink both LEDs every second. When SW1 is pressed, LED1 will stop blinking, when SW2 is pressed, LED2 will stop blinking.

Once this is working, we can confirm that ICSP, Power, oscillator, SW1, SW2, LED1 and LED2 are properly mounted.

The next step is to download the bootloader. Select the 18f14k50_usb_bootloader.hex in the ICSP programmer, and program the hex file. Remove the ICSP connector (since there shared with the USB lines), connect the USB connector with a USB cable with the Host computer, when plugging in the USB connector, hold down SW2 (program button)

If everything went ok, after a couple of seconds the Host computer will detect the USB bootloader device, it will ask for a driver. Navigate to the directory where the USB driver bootloader driver files are located, ignore the certificate warning by selecting the continue button. MCHPUSB Custom Driver.zip contains required drivers. Unzip the package to a local drive, the drivers are located in the MCHPUSB Driver\Release directory

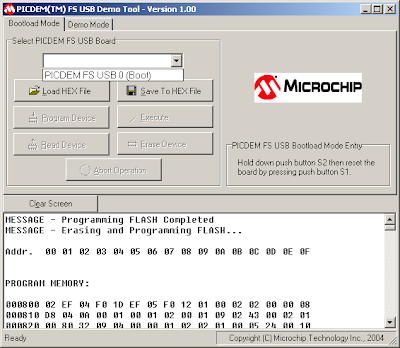

Once the drivers are installed, you can use the PDFSUSB.exe applicatio, contained in Pdfsusb.zip archive. After you unzip the file and launch the application, select the dropdown arrow of the combo box.

You should see the PICDEM FS USB 0 (BOOT) option, select it (see also screenshot). After selection, it should update the status bar, it will depict the version number (1.20) of the firmware.

When using the bootloader, you need to add the following setting when compiling a JAL file in cooperation with the bootloader:

-loader18 –no-fuse

The JAL compiler will generate special startup and interrupt code if the loader18 option is specified, the no-fuse is used to avoid overwriting wrong fuses which can mess up the bootloader (although the PDFSUSB will also emit a warning, and ask for confirmation when overwriting the fuses)

So far for part1, next blog(s) will discuss how to use the board as a USB<->RS-232 convert, use it as a USB driven I2C master or slave device and show how to make a small daughter board to capture and generate remote control infrared signals.

Hope you like it, feeback is always welcome…

Albert Faber & Richard Zengerink